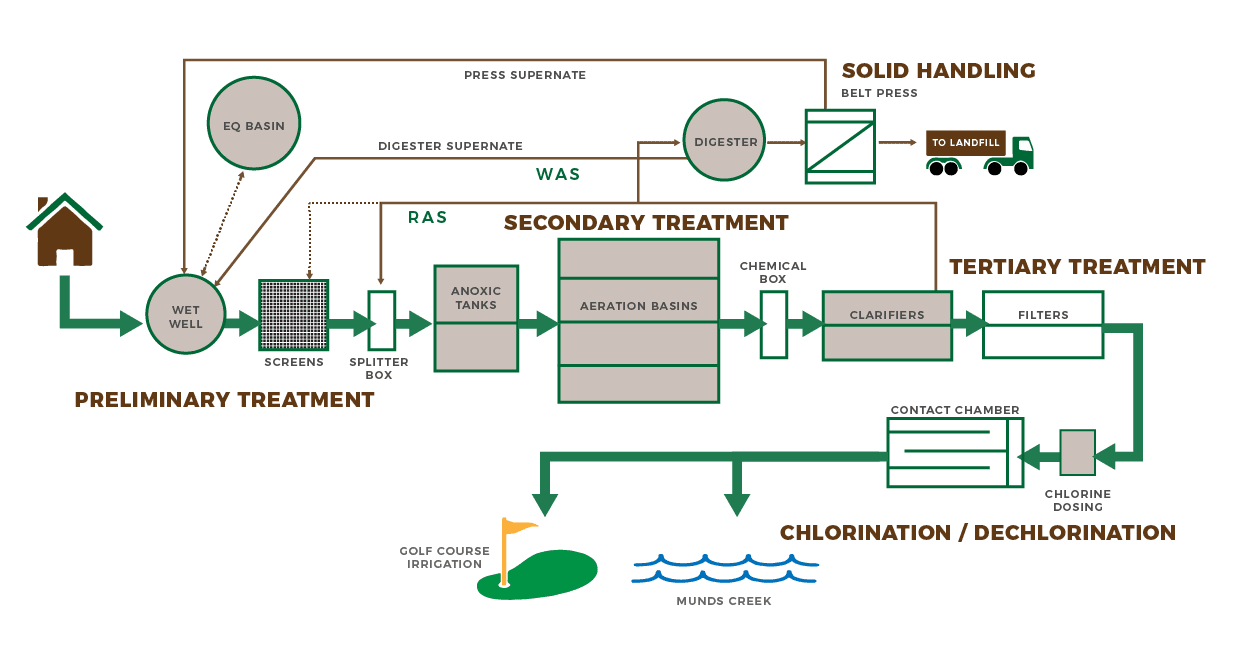

Preliminary Treatment

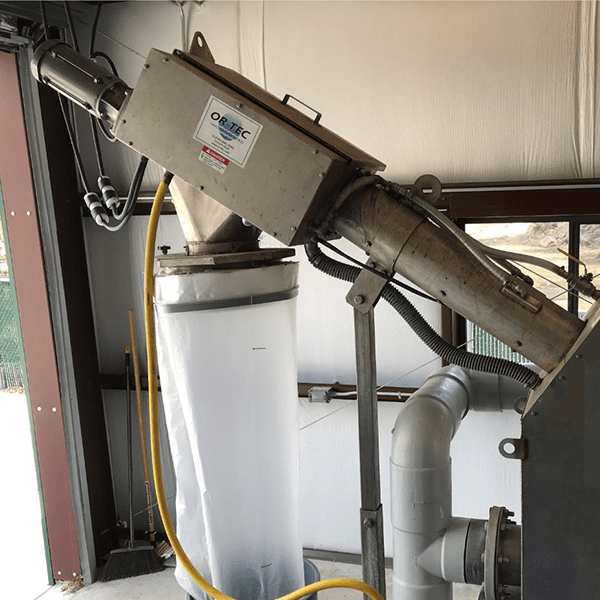

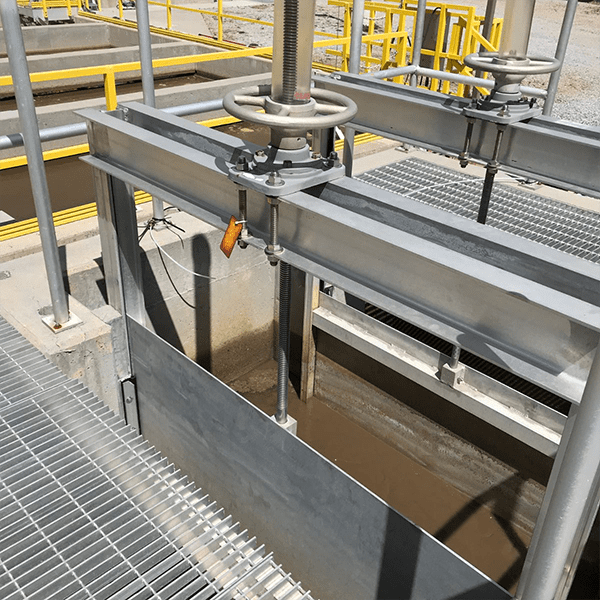

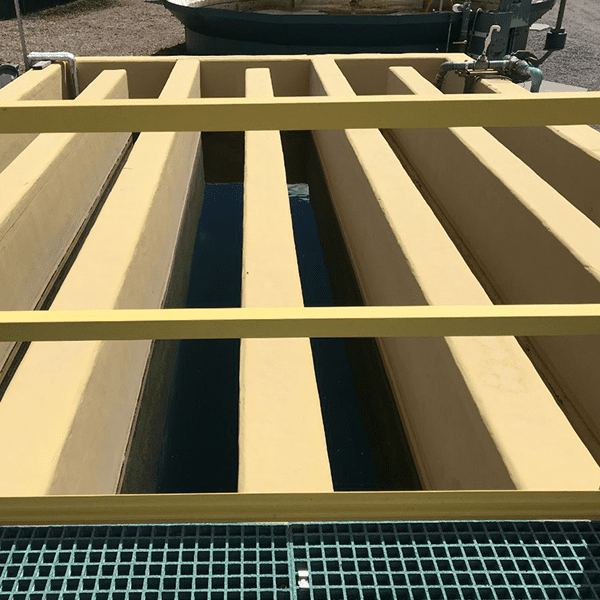

Influent flow from the Munds Park collection system enters the plant through an 18 inch gravity sewer line that first enters the PSD Wastewater Treatment Plant at the wet well. From the wet well, the influent is pumped to the headworks area of the plant where it is screened through one of two screen augers. The augers screen the influent by removing most of the larger materials such as rags, wipes, and plastics that might damage downstream equipment. Flow can also be diverted to EQ basin for later treatment. After screening, the influent flows to the splitter box where it is diverted to the anoxic tanks.

Screen Auger

Splitter Box

Secondary Treatment

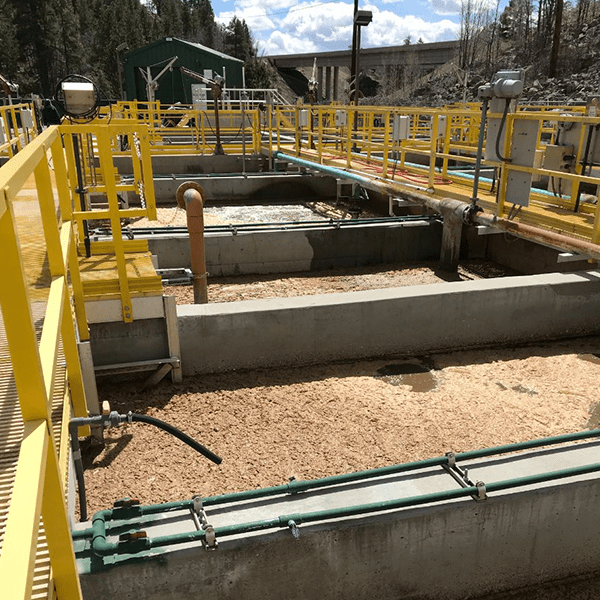

The anoxic tanks are basins that have very little dissolved oxygen. The low oxygen levels allow specialized bacteria to convert nitrate to nitrogen gas. The wastewater then flows to the aeration basin, which consists of four parallel trains, the number of which online depends on the amount of flow. The wastewater, now called mixed liquor, is aerated and further broken down by aerobic bacteria. It is also in the aeration zone where ammonia is converted to nitrites and nitrates. Some mixed liquor is recycled back to the anoxic zone to further reduce nitrogen. From the aeration trains the mixed liquor then flows through a common chemical box, where chemicals are added, then flows into the secondary clarifiers. The flow slows as it enters the clarifiers which allows the solids in the mixed liquor to settle to the bottom and the clear water to exit the clarifiers as secondary effluent. The solids, which consists mostly of microorganisms, that settle to the bottom are pushed to the one end of the clarifier. The solids are either pumped back to the splitter box to continue the work of breaking down incoming waste (RAS) or pumped to the digester where it eventually leaves the system (WAS).

Aeration Basin

Secondary Clarifier

Tertiary Treatment

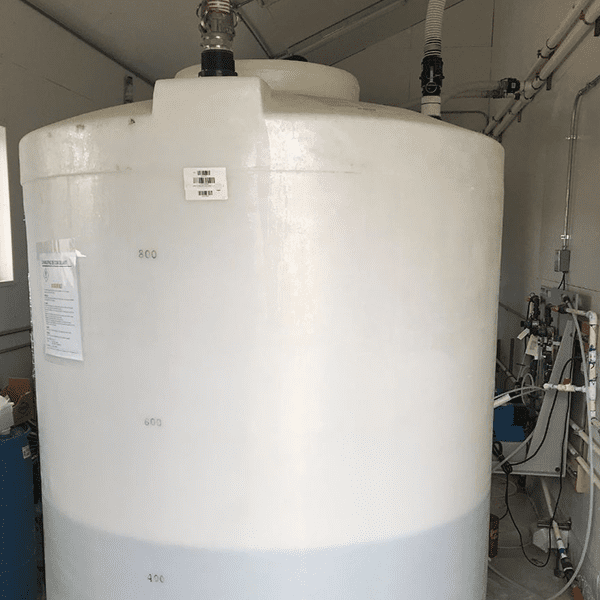

As well as biologically reducing nitrogen, the PSD plant is also designed to reduce phosphorus levels in the wastewater. This is accomplished by the addition of alum which causes the phosphorus to settle out in the secondary clarifier. Polymer is also added to aid in the settling of solids in the clarifier. The clear water leaving the secondary clarifiers is then pumped to the filter building where it filters through the traveling bridge filters. These filters consist of layers of coarse sand, fine sand, and anthracite which remove much of the remaining fine solids remaining in the secondary effluent.

Alum Tank

Traveling Bridge Filter

Disinfection/Dechlorination

The secondary effluent then flows to the chlorine dosing tank where the effluent is chlorinated before being pumped into the contact chamber where the effluent slowly flows through allowing contact time for disinfection. After passing through the contact chamber, the final effluent is either diverted towards the gold course holding ponds to be used for irrigation or dechlorinated with sulfur dioxide and sent to Munds Creek.

Chlorine Contact Chamber

Pinewood Country Club Golf Course Irrigation

Solids Handling

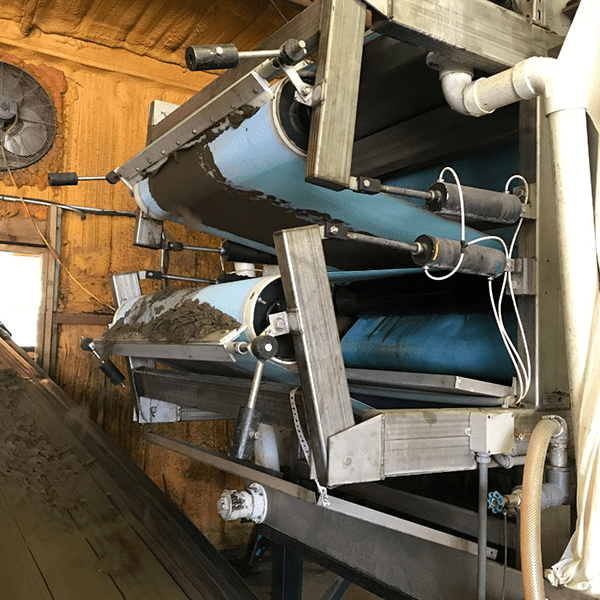

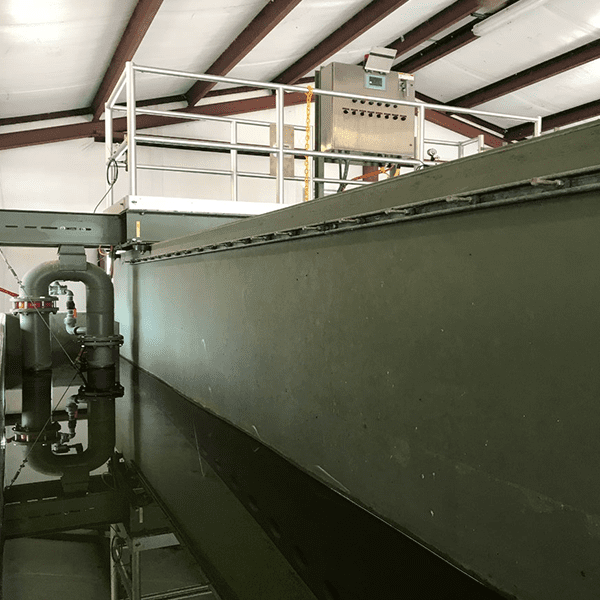

Excess solids that are pumped from the secondary clarifiers, undergo further treatment in the aerobic digester. After digestion the solids are then pumped to the belt filter press, where it is dewatered, conveyed to a disposal container, then shipped off to a landfill.

Aerobic Digester

Filter Belt Press